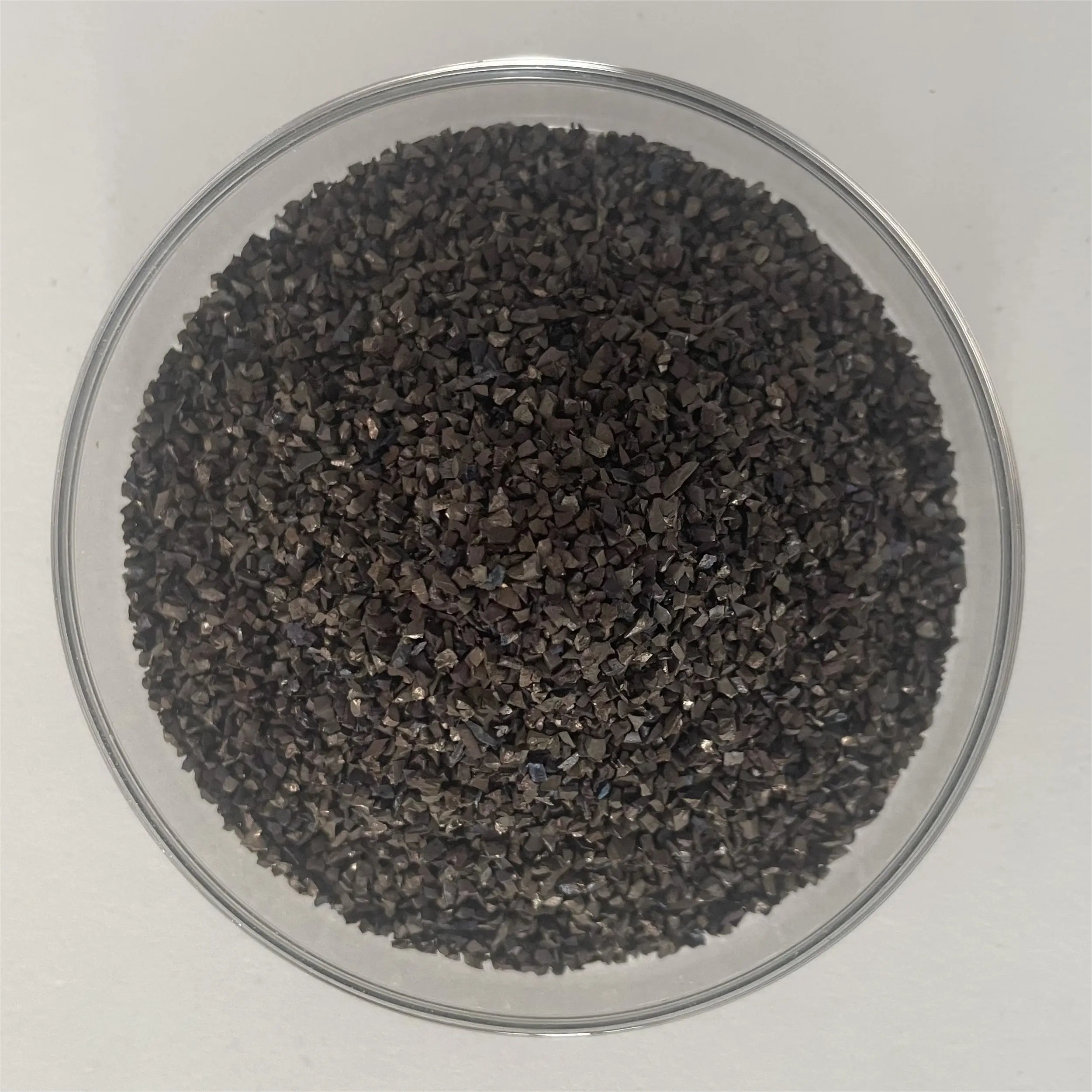

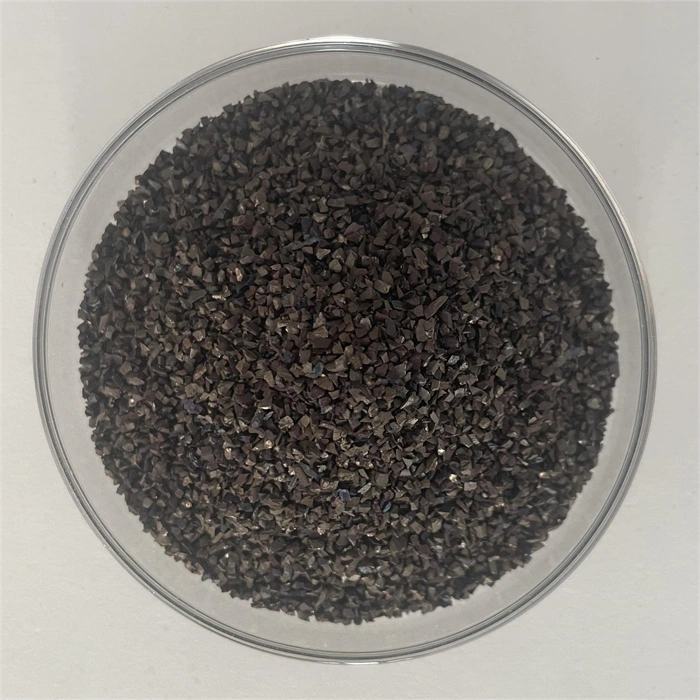

G25 Bearing Steel Grit For Stone Cutting

Bearing steel grit is a metal abrasive made from bearing steel through special processing techniques. As a high-quality steel grit material, bearing steel grit has extremely high accuracy and reliability, and can be widely used in the production of high-end industries such as stone cutting, aviation, aerospace, weapons, machinery, etc., such as high-speed motor bearings, high-speed train wheel bearings, wind turbine bearings, etc.

We provide all specification of bearing steel grit, steel grit, steel shot, stainless steel shot, steel cut wirt shot, stainless steel cut wire shot, and can customize products according to your requirements. Welcome consulting.

Bearing steel grit is a metal abrasive made from bearing steel through special processing techniques. Compared with ordinary steel grit, bearing steel grit contains precious metal chromium, which enhances fatigue life and wear resistance. Bearing steel grit is directly crushed into grit by quenching bearing steel, with sharp edges and no circular arc shape. Its efficiency is about 30% higher than ordinary steel grit.

As a high-quality steel grit material, bearing steel grit has extremely high accuracy and reliability, and can be widely used in the production of high-end industries such as stone cutting(granite cutting), aviation, aerospace, weapons, machinery, etc., such as high-speed motor bearings, high-speed train wheel bearings, wind turbine bearings, etc.

Basic Info

|

Product Name |

G25 bearing steel grit |

|

Shape |

Angular |

|

Material |

Bearing steel |

|

Model |

GP,GH,GL |

|

Granularity Range |

G10,G12,G14,G16,G18,G25,G40,G50,G80,G120 |

|

Usage |

Metal surface treatment, blasting, rust removal, cleaning, stone cutting |

|

Application Area |

Metallurgical industry, construction industry, shipbuilding industry, machinery manufacturing industry, aviation, aerospace, stone cutting |

|

Place Of Origin |

Shandong, China |

|

Package |

25 kg/bag, 1000 kg in a ton bag, 1000 kg/2000kg in a pallet. Woven bag packaging, container bag packaging, wooden pallet packaging, paper bag packaging, barrel packaging, or customized package |

|

Production Capacity |

5000 ton/year |

|

MOQ |

500 kg |

Main Index

|

Name |

Bearing Steel Grit |

|

|

chemical composition |

Carbon( C ) |

0.95~1.05% |

|

Chromium(Cr) |

1.45-1.5% |

|

|

Manganese( Mn ) |

0.25~1.20% |

|

|

Silicon( Si ) |

0.15~1.20% |

|

|

Sulfur( S ) |

≤ 0.025% |

|

|

Phosphorus( P ) |

≤ 0.025% |

|

|

Average hardness

|

GP steel grit: 47~48HRC GL steel grit :57~58HRC GH steel grit :65~68HRC |

|

|

Hardness deviation |

The maximum deviation range is ± 3.0HRC |

|

|

Microstructure |

Even tempered martensite and dispersed carbon |

|

|

Quality Standard |

SAE, ISO9001 |

|

|

Durability |

≥3000 times |

|

|

Shape |

Angular |

|

|

Minimum density (Determined by alcohol displacement method) |

7.4g/cm3 |

|

Partial Product Granularity Display

Application

The application of steel grit in the metallurgical industry

1.Blast furnace injection: Steel grit can be used as the main abrasive for blast furnace injection, used to clean the furnace bottom and slag, while also improving the permeability of the furnace bottom and promoting the smelting reaction.

2. Steel quenching: Steel grit can be used as a medium for steel quenching, which can improve the hardness and strength of steel by rapidly cooling it.

3. Casting: During the casting process, steel grit can be used as a filling material for the mold, which can improve the compactness and mechanical properties of the castings.

The Application of Steel grit in the construction Industry

1. Steel structure anti-corrosion: Steel grit can be used as a gritblasting material for steel structure anti-corrosion. By spraying steel grit on the surface of the steel structure, dirt and rust can be removed, while also improving the corrosion resistance of the steel structure.

2. Concrete gritblasting: Steel grit can be used as a material for concrete gritblasting. By spraying steel grit on the concrete surface, dirt and loose materials on the surface can be removed, while also improving the roughness and adhesion of the concrete surface.

3. Anti slip road surface: Steel grit can be used as a material for anti slip road surface. By laying steel grit on the road surface, the friction coefficient of the road surface can be improved, thereby reducing the sliding and slipping phenomenon of the road surface.

The application of steel grit in the shipbuilding industry

1. Hull rust removal: Steel grit can be used as gritblasting material for hull rust removal. By spraying steel grit on the surface of the hull, dirt and rust can be removed, thereby extending the service life of the hull.

2. Ship maintenance: During the ship maintenance process, steel grit can be used as an abrasive to remove dirt and rust from the hull surface, while also leveling the hull surface and improving its smoothness and aesthetics.

The Application of Steel grit in the Machinery Manufacturing Industry

1. gritblasting: Steel grit can be used as a gritblasting material for mechanical parts. By spraying steel grit on the surface of mechanical parts, surface quality and dimensional accuracy can be improved.

2. Abrasive grinding tools: Steel grit can be used as the raw material for abrasive grinding tools, and is used to manufacture products such as grinding wheels, abrasive belts, and gritpaper, which can meet the processing needs of different materials and hardness.

Factory display

Product catalogue

FAQ

Q1:Do you accept customized products?

A: Yes, we accept customized products, we can design and produce new products depend to your needs.

Q2:Do you supply samples?

A:Of course, we supply samples for your testing.

Q3:How about sample fee?

A: We provide free stock samples less than 1KG, if you need special samples, please contact us and we could communicate.

Q4:How can you ensure quality?

A: We will produce samples before mass production, and do final inspections before shipment.